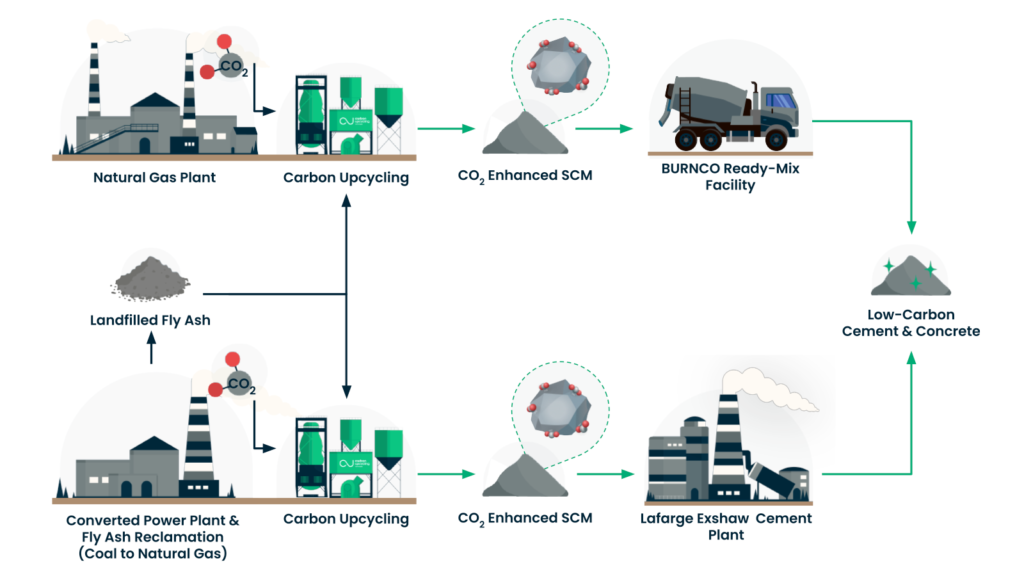

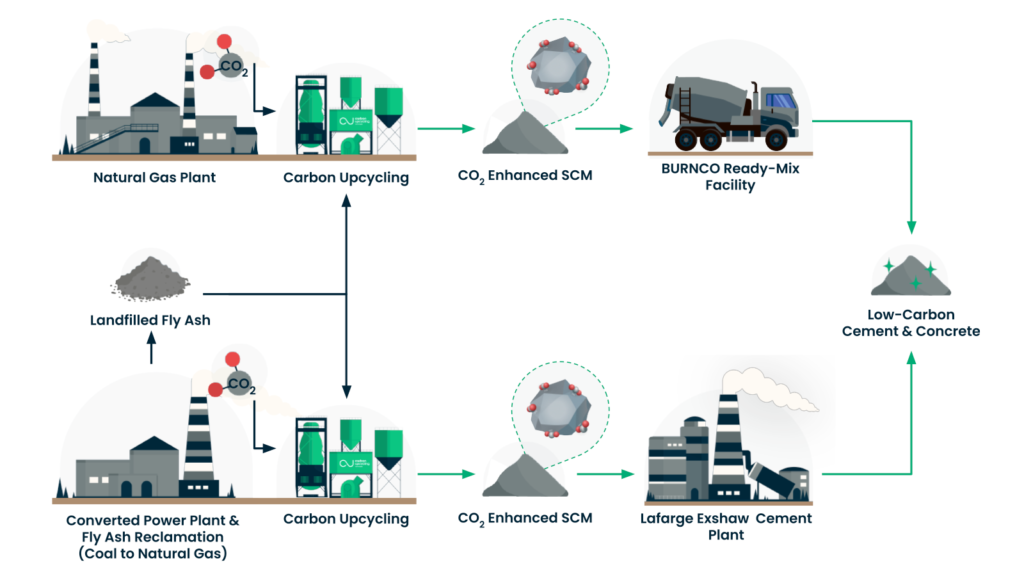

Alberta Fly Ash Reclamation

Feedstock Beneficiation

Feedstock

Coal

Feedstock

Coal

Stay up to date on everything Carbon Upcycling

Stay up to date on everything Carbon Upcycling