Location

Ontario, CA

Annual Impact

1,400 tCO2 Sequestered

11,500 tCO2 Abated

14,000 t of Byproducts Upcycled

Project Deployment

2024

Partners

Ash Grove, a CRH

Company

Location

Ontario, CA

Annual Impact

1,400 tCO2 Sequestered

11,500 tCO2 Abated

14,000 t of Byproducts Upcycled

Project Deployment

2024

Partners

Ash Grove, a CRH

Company

Location

Ontario, CA

Project Overview

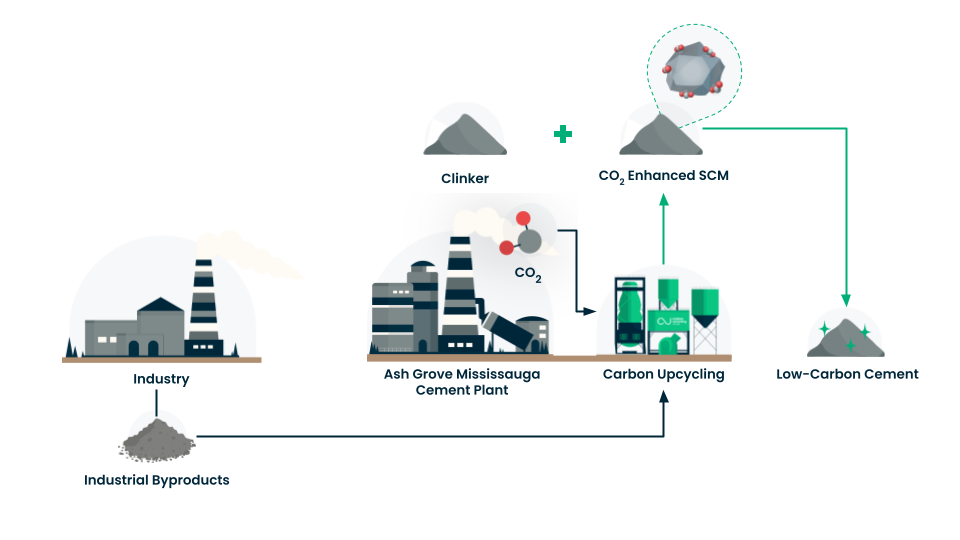

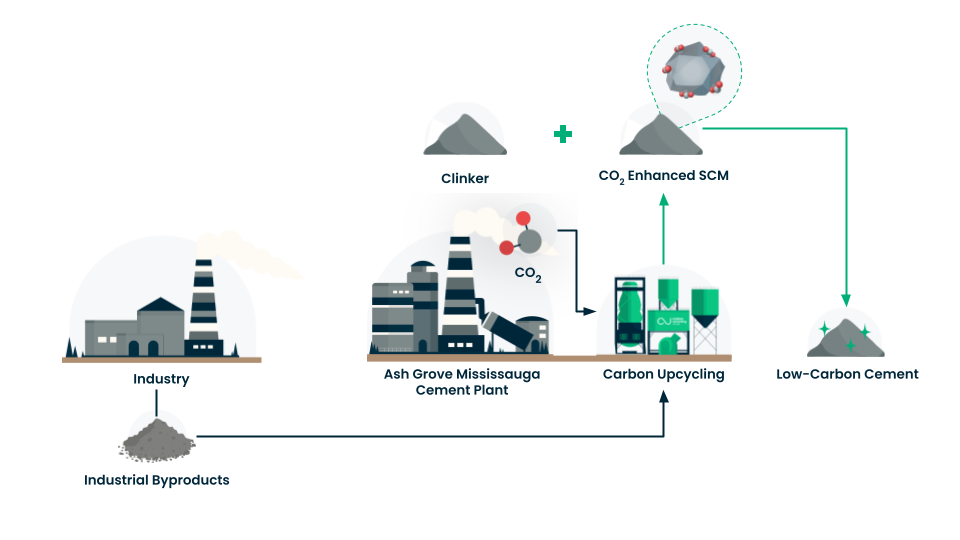

Carbon Upcycling in partnership with Ash Grove (a CRH company), a global leader and pioneer in the cement industry, will be deploying our first industrial project at their Mississauga cement plant.

Our technology will produce a high-performance cementitious material from a locally-sourced industrial byproduct and permanently sequester CO2 emissions from the cement kiln.

The low-carbon material will be used to reduce the clinker ratio of the Mississauga cement plant, significantly reducing the embodied carbon of the cement.

Location

Ontario, CA

Project Deployment

2024

Annual Impact

1,400 tCO2 Sequestered

11,500 tCO2 Abated

14,000 t of Byproducts Upcycled

Partners

Ash Grove, a CRH

Company

Project Overview

Carbon Upcycling in partnership with Ash Grove (a CRH company), a global leader and pioneer in the cement industry, will be deploying our first industrial project at their Mississauga cement plant.

Our technology will produce a high-performance cementitious material from a locally-sourced industrial byproduct and permanently sequester CO2 emissions from the cement kiln.

The low-carbon material will be used to reduce the clinker ratio of the Mississauga cement plant, significantly reducing the embodied carbon of the cement.

“We have chosen to further develop our existing partnership with Carbon Upcycling as its technology solution aligns directly with our circular, zero-waste sustainability values. The cement plant integration we are supporting means this technology will be deployed at commercial scale in one of the largest cement plants in Canada, demonstrating a cost-effective, circularity-based method of producing low-carbon cement.”

Eduardo Gomez Mendoza, Head of CRH Ventures.

“We have chosen to further develop our existing partnership with Carbon Upcycling as its technology solution aligns directly with our circular, zero-waste sustainability values. The cement plant integration we are supporting means this technology will be deployed at commercial scale in one of the largest cement plants in Canada, demonstrating a cost-effective, circularity-based method of producing low-carbon cement.”

Eduardo Gomez Mendoza, Head of CRH Ventures.

Related Projects

Cemex Rugby Cement Plant

Cement Plant Integration

Ash Grove Mississauga Cement Plant

Cement Plant Integration

Alberta Fly Ash Reclamation

Feedstock Beneficiation

Related Projects

Cemex Rugby Cement Plant

Cement Plant Integration

Ash Grove Mississauga Cement Plant

Cement Plant Integration

Alberta Fly Ash Reclamation

Feedstock Beneficiation

Cemex Rugby Cement Plant

Cement Plant Integration

Ash Grove Mississauga Cement Plant

Cement Plant Integration

Alberta Fly Ash Reclamation

Feedstock Beneficiation

Contact Us

Have a project in mind?

Connect with our team to learn how we upcycle

materials into low-carbon solutions!

Connect with our team to learn how we upcycle

materials into low-carbon solutions!

Have a project in mind?

Connect with our team to learn how we upcycle materials into low-carbon solutions!

Connect with our team to learn how we upcycle materials into low-carbon solutions!

Stay up to date on everything Carbon Upcycling

Stay up to date on everything Carbon Upcycling