Location

Rugby, Uk

Annual Impact

1,600 tCO2 Sequestered

15,000 tCO2 Abated

16,500 t of Byproducts Upcycled

Project Deployment

2024

Funding

£2.3 Million grant from UK Research and Innovation (UKRI)

Partners

Cemex, MKD32, Glass Technology Services

Location

Rugby, Uk

Annual Impact

1,600 tCO2 Sequestered

15,000 tCO2 Abated

16,500 t of Byproducts Upcycled

Project Deployment

2024

Funding

£2.3 Million grant from UK Research and Innovation (UKRI)

Partners

Cemex, MKD32, Glass Technology Services

Location

Rugby, Uk

Project Overview

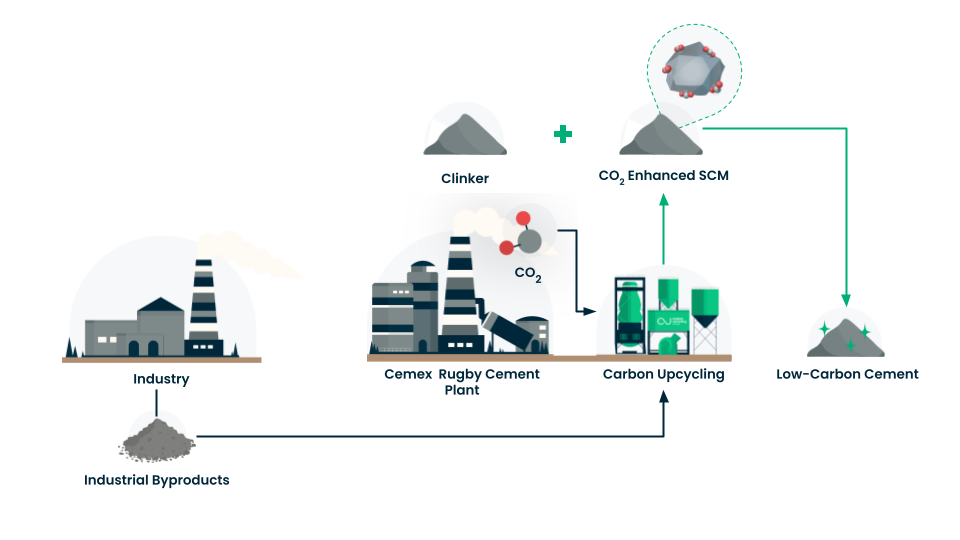

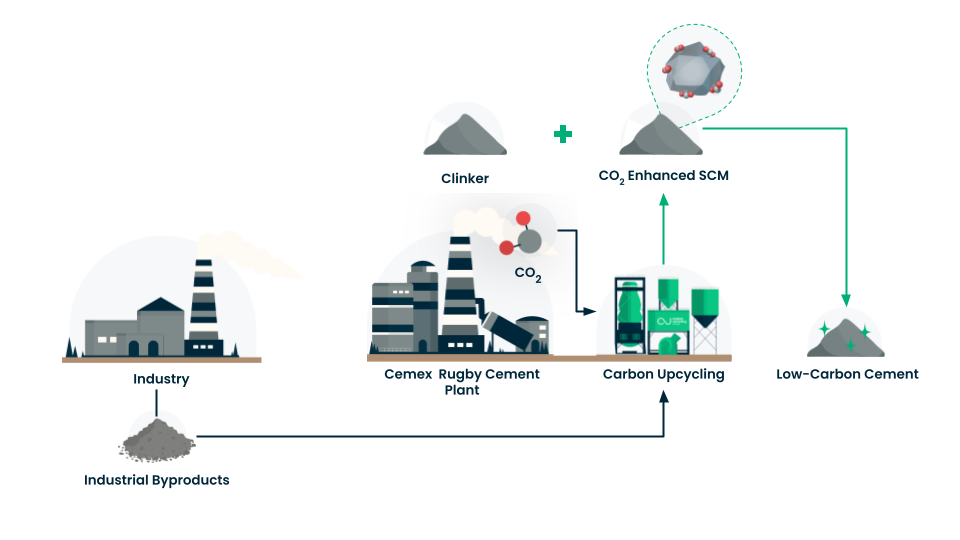

Carbon Upcycling in partnership with CEMEX, a global cement producer and a leading sustainable construction materials and solutions company, will be developing an industrial-scale plant that produces cement additives by sequestering CO2 in industrial byproducts. The project will take place at the Rugby cement plant and will be the first deployment of the Carbon Upcycling technology in Europe.

Our technology will produce a high-performance cementitious material from locally-sourced industrial byproducts and permanently sequester CO2 emissions from the cement kiln.

The low-carbon material will be used to reduce the clinker ratio of the Rugby cement plant, significantly reducing the embodied carbon of the cement.

Location

Rugby, Uk

Project Deployment

2024

Annual Impact

1,600 tCO2 Sequestered

15,000 tCO2 Abated

16,500 t of Byproducts Upcycled

Partners

Cemex, MKD32, Glass Technology Services

Funding

£2.3 Million grant from UK Research and Innovation (UKRI)

Project Overview

Carbon Upcycling in partnership with CEMEX, a global cement producer and a leading sustainable construction materials and solutions company, will be developing an industrial-scale plant that produces cement additives by sequestering CO2 in industrial byproducts. The project will take place at the Rugby cement plant and will be the first deployment of the Carbon Upcycling technology in Europe.

Our technology will produce a high-performance cementitious material from locally-sourced industrial byproducts and permanently sequester CO2 emissions from the cement kiln.

The low-carbon material will be used to reduce the clinker ratio of the Rugby cement plant, significantly reducing the embodied carbon of the cement.

“We are committed to lead efforts that support the decarbonization of the cement sector by combining our extensive industry knowledge with the most promising and innovative solutions. At Cemex, we aim to reach net-zero by 2050 and this project with Carbon Upcycling is an important milestone towards utilizing captured carbon to help achieve this goal. This project will help us to double the industry’s use of cement replacements by 2030 and allow Cemex to participate in a circular economy project.”

Gonzalo Galindo, Head of Cemex Ventures

“We are committed to lead efforts that support the decarbonization of the cement sector by combining our extensive industry knowledge with the most promising and innovative solutions. At Cemex, we aim to reach net-zero by 2050 and this project with Carbon Upcycling is an important milestone towards utilizing captured carbon to help achieve this goal. This project will help us to double the industry’s use of cement replacements by 2030 and allow Cemex to participate in a circular economy project.”

Gonzalo Galindo, Head of Cemex Ventures

Related Projects

Cemex Rugby Cement Plant

Cement Plant Integration

Ash Grove Mississauga Cement Plant

Cement Plant Integration

Alberta Fly Ash Reclamation

Feedstock Beneficiation

Related Projects

Cemex Rugby Cement Plant

Cement Plant Integration

Ash Grove Mississauga Cement Plant

Cement Plant Integration

Alberta Fly Ash Reclamation

Feedstock Beneficiation

Cemex Rugby Cement Plant

Cement Plant Integration

Ash Grove Mississauga Cement Plant

Cement Plant Integration

Alberta Fly Ash Reclamation

Feedstock Beneficiation

Contact Us

Have a project in mind?

Connect with our team to learn how we upcycle

materials into low-carbon solutions!

Connect with our team to learn how we upcycle

materials into low-carbon solutions!

Have a project in mind?

Connect with our team to learn how we upcycle materials into low-carbon solutions!

Connect with our team to learn how we upcycle materials into low-carbon solutions!

Stay up to date on everything Carbon Upcycling

Stay up to date on everything Carbon Upcycling