Cemex Rugby Cement Plant

Cement Plant Integration

Ash Grove Mississauga Cement Plant

Cement Plant Integration

Alberta Fly Ash Reclamation

Feedstock Beneficiation

Cemex Rugby Cement Plant

Cement Plant Integration

Ash Grove Mississauga Cement Plant

Cement Plant Integration

Alberta Fly Ash Reclamation

Feedstock Beneficiation

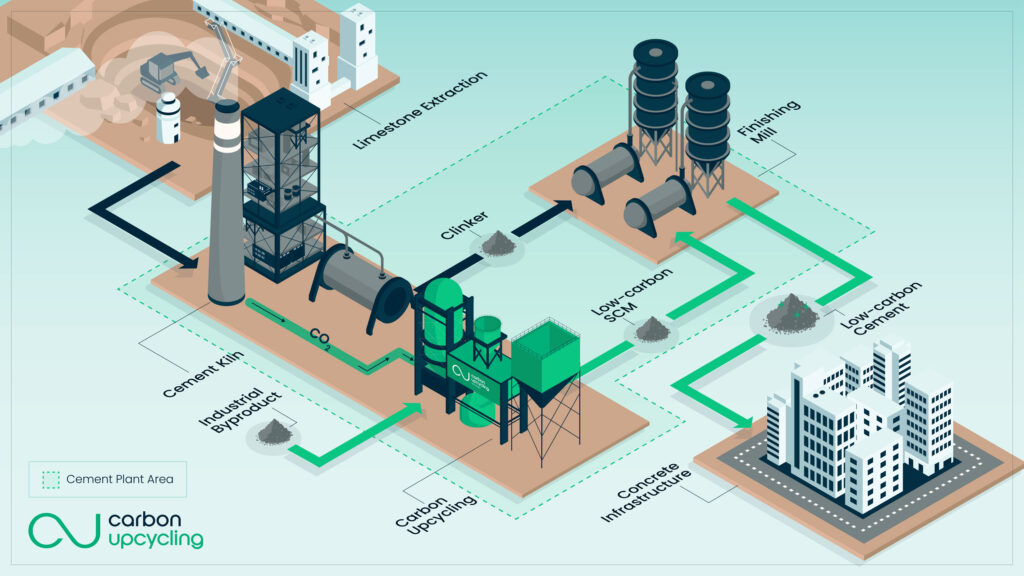

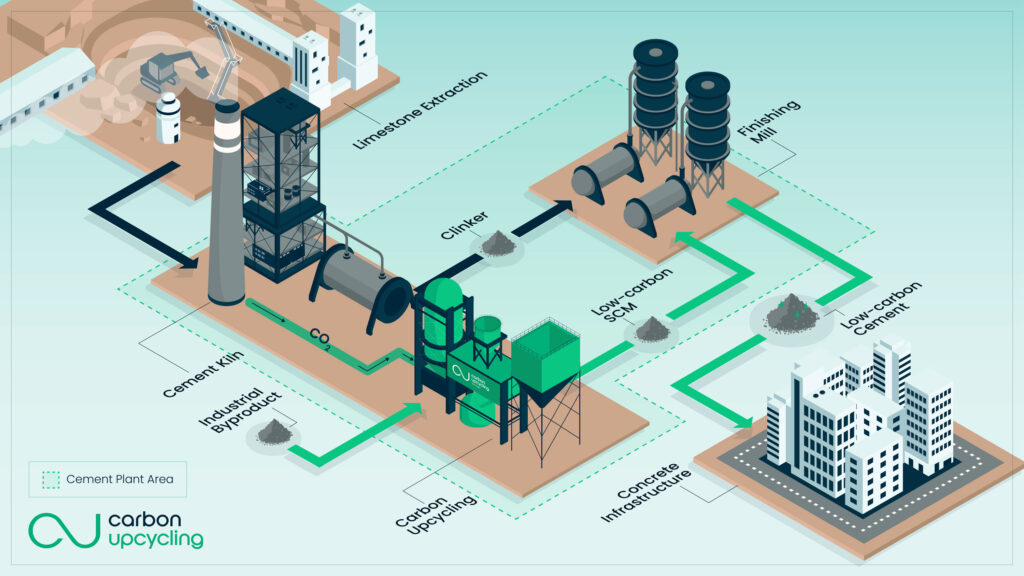

Unlocking Low-Carbon SCMs

Carbon Upcycling’s technology is unlocking the next frontier of supplementary cementitious materials (SCMs) – sequestering carbon emissions while transforming low-value feedstocks and industrial byproducts into high-performance cementitious material.

SCM Development

Decarbonize Cement with SCMs

NEW SCM Supply

Carbon Utilization

More Cement, Fewer Emissions

With over 40+ feedstocks validated, we provide a diverse, steady, local supply of SCMs.

CO2 emissions from the cement kiln are mineralized into the material feedstock – sequestering emissions permanently to produce a low-carbon SCM.

Our SCMs can reduce up to 50% of clinker in cement–maintaining exceptional performance while increasing production at cement facilities.

NEW SCM Supply

With over 40+ feedstocks validated, we provide a diverse, steady, local supply of SCMs.

Carbon Utilization

CO2 emissions from the cement kiln are mineralized into the material feedstock – sequestering emissions permanently to produce a low-carbon SCM.

More Cement, Fewer Emissions

Our SCMs can reduce up to 50% of clinker in cement–maintaining exceptional performance while increasing production at cement facilities.

Integration

A Practical Approach to Decarbonization

Our technology can scale to meet the SCM production opportunities for the cement plant. It integrates into the facility during scheduled downtime, ties into the kiln flue stack to sequester emissions and delivers SCMs directly into the material handling system.

Contact Us

Connect with our team to learn how we upcycle

materials into low-carbon solutions!

Connect with our team to learn how we upcycle materials into low-carbon solutions!

Stay up to date on everything Carbon Upcycling

Stay up to date on everything Carbon Upcycling